Rug making is very unique. At Rugs & More we carry a large selection of rugs. Whether it is Modern, Antique, Persian or Classical. Our experts will help guide you in selecting the right rug or even custom make one.

Select your colors

Some clients find it impossible to have a rug custom made with out them actually seeing what it will turn out like. Well at Rugs & More we guarantee customer satisfaction. Most importantly we go out of our way to order you a 3×5 rug sample with the colors and design you select. We do not move forward until you are completely happy with it.

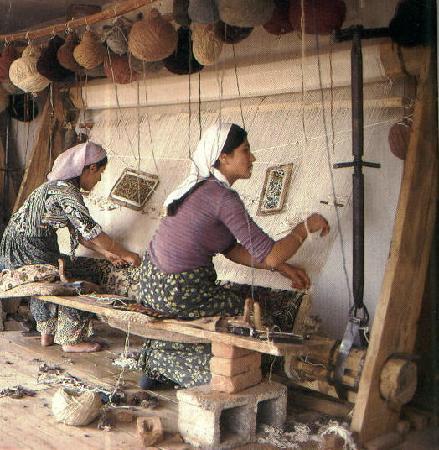

Once we get your approval, we send out your design to weavers that will take about 10-12 month making it. It all depends on the size and design. But their is more to just weaving it. How they get the wool and dyes comes into play to be able to make it happen.

Wool is the textile fiber obtained from sheep and other animals, including cashmere and mohair from goats. Furthermore, wool is the most popular material for making rugs. It is strong, soft, long lasting and beautiful. Once unprocessed wool arrives at a rug making workshop, it is separated by hand to break up the clumps and remove any foreign materials that may have got stuck in it. Then it is fed into a machine that pulls it into individual strands.

The stands are then spun into yarn. In previous centuries, wool was spun by hand on rudimentary spinning wheels. The yarn is then washed to remove the dust and grease thoroughly. The process involves submerging it in a detergent bath, wringing it out several times, and then washing it with clean water to remove the detergents. The washed yarn is dried in the sun for two to three days.

The washed yarn is hung onto a rack and submerged in a dye, which is created by using a combination of natural or synthetic elements to produce the perfect hue. Allowing the dye to work its way into the yarn, it is heated to a near-boiling temperature for a short period of time. The longer the time, the darker the hue. The dyed yarn is then put out in the sun to dry.

The materials that go into a weaving rugs are as important as the design and workmanship. They contribute enormously to the overall impression of the rug.For instance its color, texture, tactile feel, and above all its durability. Natural dyes were the only type available for centuries, and have a distinct way of aging. This is one clear, tangible example of how the materials used to make rugs have a tremendous impact on the overall look and feel of the finished piece.

Once the yarn is dry, it is ready to be woven into a carpet. There are primarily three ways to weave a carpet: knotting, tufting and hooking.

First, an artist draws a design for the rug on a special graph paper. A frame is then prepared by stretching columns of thread, called warps, vertically down the loom. Warps are usually made of cotton. The weaver then weaves the yarn knot-by-knot on the loom using a knotting method, such as Turkish knot, Persian knot and Tibetan knot

Rugs and carpets have been made for many centuries. The first rugs were made by tribal shepherds who needed heavy clothes to shield themselves from the cold and wind, who soon started to use them as floor coverings. Over the centuries, rug makers developed techniques to weave amazingly beautiful patterns and turned rug making into a form of fine art.

@ Santa Barbara Design Center / Rugs & More

410 Olive St.Santa Barbara,CA93101

Phone:(805) 962-2166 Email:[email protected]

Open: Mon-Sat 9:30 to 5:30